A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. As a necessary byproduct, refrigeration creates waste heat that must be exhausted to ambient or, for greater efficiency, recovered for heating purposes. Concerns in design and selection of chillers include performance, efficiency, maintenance, and product life cycle environmental impact. NEC AIR COMPRESSORS AND PUMPS

WATER COOLED CHILLER:

Industrial Cooled chiller technology:

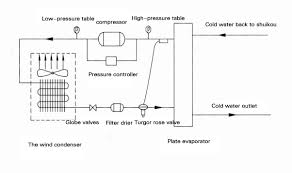

Industrial chillers typically come as complete, packaged, closed-loop systems, including the chiller unit, condenser, and pump station with recirculating pump, expansion valve, no-flow shutdown, internal cold water control. The internal tank helps maintain cold water temperature and prevents temperature spikes from occurring. Closed-loop industrial chillers recirculate a clean coolant or clean water with condition addititives at a constant temperature and pressure to increase the stability and reproducibility of water-cooled machines and instruments. The water flows from the chiller to the application’s point of use and back.

If the water temperature differentials between inlet and outlet are high, then a large external water tank would be used to store the cold water. In this case the chilled water is not going directly from the chiller to the application, but goes to the external water tank which acts as a sort of “temperature buffer.” The cold water tank is much larger than the internal water water goes from the external tank to the application and the return hot water from the application goes back to the external tank, not to the chiller. NEC AIR COMPRESSORS AND PUMPS

The less common open loop industrial chillers control the temperature of a liquid in an open tank or sump by constantly recirculatingRDT it. The liquid is drawn from the tank, pumped through the chiller and back to the tank. in industrial water chillers is the use of water cooling instead of air cooling. In this case the condenser does not cool the hot refrigerant with ambient air, but uses water that is cooled by a cooling tower. This development allows a reduction in energy requirements by more than 15% and also allows a significant reduction in the size of the chiller, due to the small surface area of the water-based condenser and the absence of fans. Additionally, the absence of fans allows for significantly reduced noise levels.

Most industrial chillers use refrigeration as the media for cooling, but some rely on simpler techniques such as air or water flowing over coils containing the coolant to regulate temperature. Water is the most commonly used coolant within process chillers, although coolant mixtures (mostly water with a coolant additive to enhance heat dissipation) are frequently employed.

Industrial chiller selection

Important specifications to consider when searching for industrial chillers include the total life cycle cost, the power source, chiller IP rating, chiller cooling capacity, evaporator capacity, evaporator material, evaporator type, condenser material, condenser capacity, ambient temperature, motor fan type, noise level, internal piping materials, number of compressors, type of compressor, number of fridge circuits, coolant requirements, fluid discharge temperature, and COP (the ratio between the cooling capacity in RT to the energy consumed by the whole chiller in KW). For medium to large chillers this should range from 3.5 to 7.0, with higher values meaning higher efficiency. Chiller efficiency is often specified in kilowatts per refrigeration ton (kW/RT).

Process pump specifications that are important to consider include the process flow, process pressure, pump material, elastomer and mechanical shaft seal material, motor voltage, motor electrical class, motor IP rating and pump rating. If the cold water temperature is lower than −5 °C, then a special pump needs to be used to be able to pump the high concentrations of ethylene glycol. Other important specifications include the internal water tank size and materials and full load current.

Control panel features that should be considered when selecting between industrial chillers include the local control panel, remote control panel, fault indicators, temperature indicators, and pressure indicators.

Additional features include emergency alarms, hot gas bypass, city water switchover, and casters.

Demountable chillers are also an option for deployment in remote areas and where the conditions may be hot and dusty. NEC AIR COMPRESSORS AND PUMPS