AIR COMPRESSORS

AN ISO 9001:2015 CERTIFIED COMPANY

THE QUALITY MANAGEMENT SYSTEM

We Proud to say we Honored with an Awards

About Us

Established in the year 1988, National Equipment Company is currently one of the top manufacturing companies in Tamil Nadu. Especially we providing high quality, low budgeted as well as minimal maintenance Air Compressors and Pump-sets. Above all, professionally designed, manufactured and assembled with care at our ultra-modern manufacturing units. Additionally, our units are located in Coimbatore .

Since 33 years of professional experience in the industry has led to providing not only quality products but also high satisfactory customer service. As a result, we successfully manage a high profile book of business including numerous industrial users from India .

Our Air Compressor is one of our best sellers, because of its high efficiency, affordability and premium quality rating, tested and rated by our experts .

JUMBO AIR COMPRESSOR

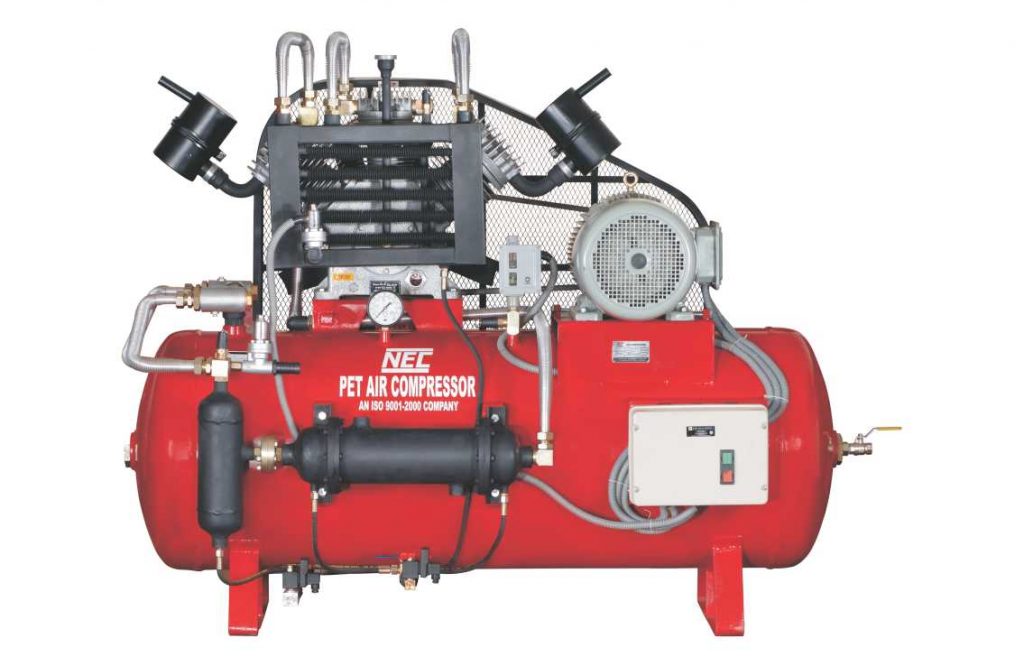

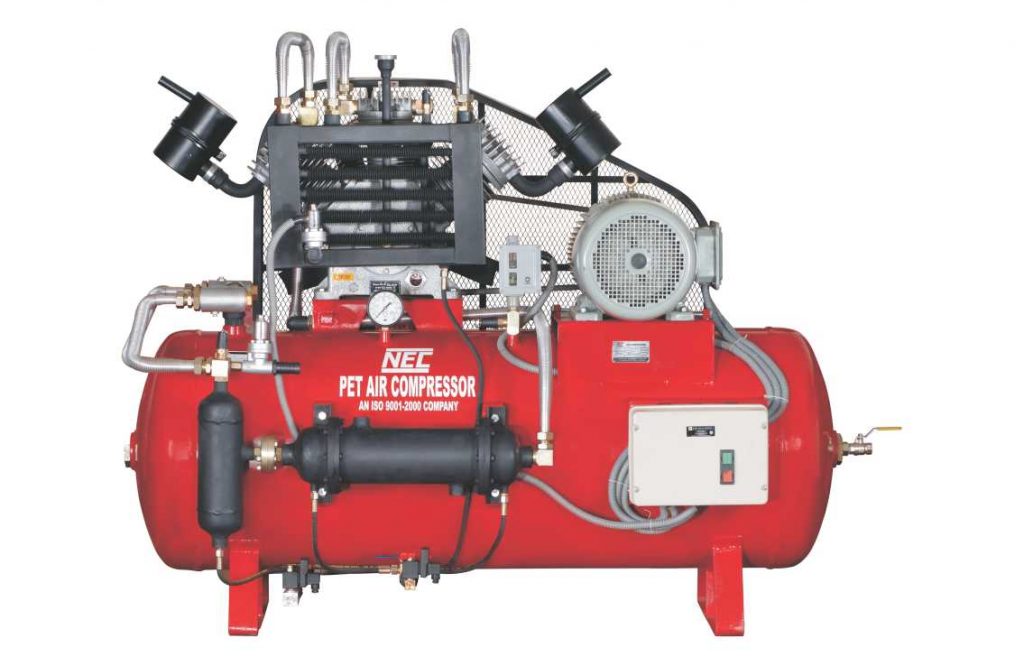

PET AIR COMPRESSOR

15HP AIR COMPRESSOR

10HP AIR COMPRESSOR

7.5HP AIR COMPRESSOR

5HP AIR COMPRESSOR

3HP AIR COMPRESSOR

2HP AIR COMPRESSOR

1.5HP AIR COMPRESSOR

1HP AIR COMPRESSOR

0.5HP AIR COMPRESSOR

Painter Model Compressors

AIR DRYER

Screw Compressors

Pneumatic Air Gun

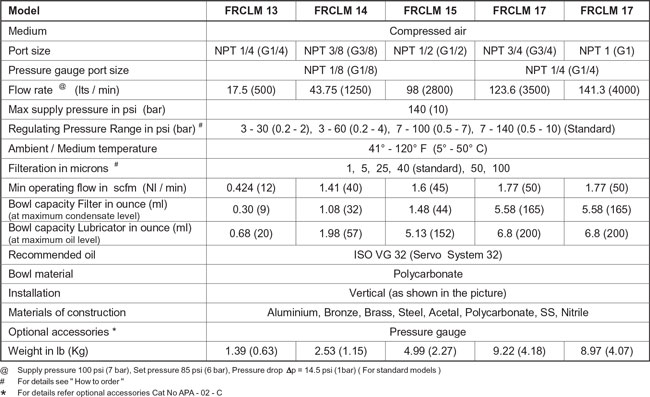

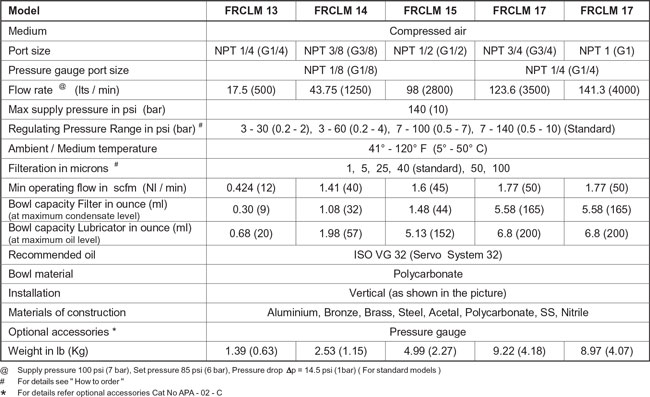

Filters

Air Hose / Painting Gun / Tire Pressure Gauge

Other Products

Inflators

Garage Equipments

Pumpsets

Quality Parameters

Our main objective is delivering elite products, not only in terms of quality but also in quantity. We achieve these parameters through professional insight, for instance, by using highly skilled manpower along with supreme standard machinery and tools. In essence, our team comprises of qualified managers, supervisors, quality controllers and also the best marketing strategists from the industry. We provide well structured and easy to understand customer guidance as well as extended maintenance packages along with most of our ranges.

During the delivery, all our products are thoroughly checked and packaged by our professional dispatch team to ensure safety and quality at your door-step. Henceforth, prioritizing the satisfaction of our customers and the standard of our service.

Apart from Air Compressors, we also provide additional components such as Air dryers, Air filters, Drain valves and Receiver tanks. In conclusion, with extensive experience in delivering high range products, we assure the best compressors at very affordable price. Generally compressor users in Pneumatic Application. Especially made for Industrial Usage. NEC good efficient Comparatively with other compressors. NEC made equally good mark in India with manufacturers of our Products .

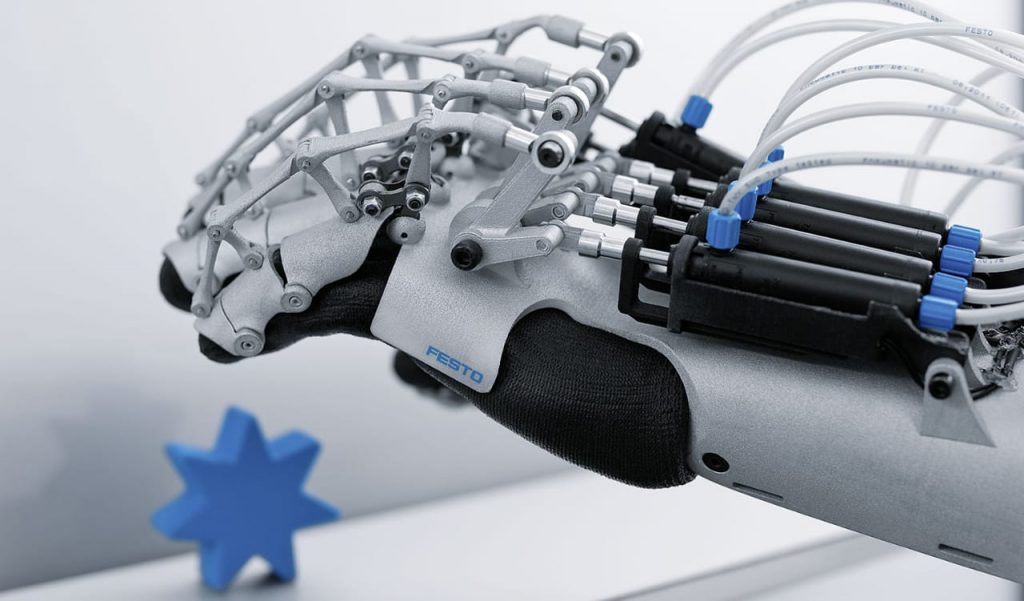

Reciprocating Air Compressors

Reciprocating compressors are commonly called as piston air compressor. NEC is one among the few reciprocating air compressor manufacturers in Coimbatore . At NEC Compressor we make sure that we manufacture all of the Cast Iron parts compared to the other reciprocating air compressor manufacturers who tend to outsource them from low quality suppliers. Especially we ensure only the top quality reciprocating air compressor manufacturer parts make it into the assembly line to ensure proper standards are maintained. Finally Our components meet strict tolerance parameters with the help of CNC machining centres.

Mainly all our piston compressor manufacture maintain a constant chemical composition which is carefully monitored in our laboratory. Specially the remaining piston air compressor manufacturer parts are obtained from only the highest grade suppliers like skf, IPL, Crompton, L&T, Fenner, etc. We are one of the very few reciprocating air compressor suppliers in Coimbatore that still provides standard over decades. Accordingly Our reciprocating compressor are classified into industrial air compressor, portable air compressor, pet air compressor and borewell air compressor.

Parts of the Air Compressor

For further understanding, we have listed the different parts of our Pneumatic Air compressor. It is categorized into three parts such as primary devices, Safety devices and Interlocking devices.

Reciprocating Air Compressor Unit

• Crankcase • Cylinder Head • Connecting Rod and Crankshaft Assembly • Piston • Inter Cooler

• Electrical Motor • Drive System • Electric Control • Air Receiver

Safety Devices

• After Cooler • Air Receiver/Delivery Pipe • Delivery Unloaded Valve

Interlocking Device

1) Pressure Switch • Non-return Valve • Hobby and do-it-yourself purposes • Tyre inflation Features

• Built-in thermal overload relay for motor protection • Shear strength • Precisely engineered

• Longer service life

Working Principle

Pneumatic Reciprocating Air Compressors

The following explains the working principle of the Pneumatic Reciprocating Air Compressor which progressively converts power into potential energy with the help of power or oil engine. As a result, the vertical protector angle actions function efficiently in minimal wear and tear with the oil lubrication. Firstly, the atmospheric air is withdrawn inside the cylinder through intake valves and the same is repeated. Air is continuously pulled inside the cylinder through the valves significantly, as a part of the process . Secondly, the drawn air is stored in a air receiver.

To enumerate, the air that exits from the compressor cylinders is termed as the Piston Displacement. Significantly, the displaced air in which the pressure and volume conversion happens is through either a single stage Air Compressor or two stage Air Compressor. Following, Piston displacement transfers air to the air tank continuously and this displaced air develops pressure inside the air receiver consequently.

To summarize, the requirement of pressure, the pressure and volume created from various phases such as following :-

• Single • Double • Triple

Therefore, depending on the volume of pressure the different compressors categorized as Low pressure Air Compressors , High pressure Reciprocating Air Compressors, Compressor driven by Single phase Electric Motors, Three Phase Electric Motors or Oil Engine.

Range

Overall, National Equipment Company manufactures varied range of Pneumatic Reciprocating compressors and is suited to fit different requirements. Our wide range of available models markedly suite wider range of customer needs. Our available models include,

• Air storage capacity available in vertical mounted Air Receiver and Horizontal Air Receiver

• Available Air Tank Capacity starting from 50 liters to 10,000 liters

Applications

The Pneumatic Reciprocating Air Compressors is applicable not only for industrial but also for domestic purposes. The Air Compressor has a flexibility in providing high and controlled pressure and can easily be monitored and controlled, henceforth, making it one of the widely used typology as followings

• Industrial• CNC / VMC Machines• Petrol Bunk• Painting• Textile Mills/Hospital/Dental• PneumaticTools

• AirTool• Service Station• Railway• Tyre Changing• Auto body Shop• Wood working• Lab Institution

Screw Air Compressors

NEC SMV series rotary screw air compressors are known for their reliability, low maintenance requirements, and small footprint. And also these features make them ideal for industrial applications where size, efficiency, and cost matter. The SMV series screw air compressors from NEC provide efficient air-oil separation and highly efficient belt drive and also direct drive transmission etc .

Air leaving a standard screw or piston compressor will usually have considerable water content, and a high concentration of oil as well as other contaminants. Specially NEC compressors compressed air filters are efficient in removing contaminates from compressed air after compression has taken place.

Basically there are various types of filters, applicable for different pneumatic applications. NEC compressors produces supreme quality air filters utilizing our rich expertise and more than three decades experience in the air compressors manufacturing industry.

Secondly , NEC oil-free screw air compressors comply with class zero oil standards with no breakdowns & workable economics. Especially we designed & manufactured with our in-house oil-free technology like oil-free air ends and unique eta-V rotor design, helping deliver the highest quality air during the manufacturing process.

Air Dryer

Further we bring forth for our clients a wide collection of Air Dryer. Generally these Air Dryer manufactured at our state-of-the-art infrastructure facility. Especially Latest machines and advanced technology employed by our experienced professionals following standards and norms of the industry.

Basically Compressed air systems could be best sources for energy savings. But also on the supply side where air is compressed, it is vital to utilize the right combination of compressors, air receivers as well as air dryers. Further using industry standard accessories will enable the system to run more efficiently and effectively . Certainly an air dryer is an integral part in the air treatment system. In addition Selecting the relevant air dryer as well as compressed air filter is very critical.

Especially NEC compressors air dryers are supreme quality treatment products that will considerably improve your entire air compressor system. Presently our extensive knowledge and expertise in this field is a key factor to the success of your compressed air system are congue afterwords .