AN ISO 9001:2015 CERTIFIED COMPANY

THE QUALITY MANAGEMENT SYSTEM

National Equipment Company

Leveraging on our vision to achieve sustainable growth and success, We National Equipment Company have established ourselves as an eminent Agricultural Pumps and Domestic Pumps in the Year 1988 , From the Year of 1994, we have started Domestic Borewell Compressor in coimbatore , Reciprocating Air Compressors, Garage Equipments, Manufacturer and trader of India.

We are well known for our our never compromising quality control policy for our product range as well as services with hold on ISO 9001:2015 certification. Due to the unparalleled quality of our products, we have acquired the membership of CODISSIA, SIMA, TAPMA, SITARC, COPMA, COCIA .Owing to transparent business policy and impeccable quality products, our organization has gained immense popularity across the country, to render services, hence we supply our products to all the States in India through Distributors, Dealers and now in Online Customers .

We Proud to say we Honored with an Awards

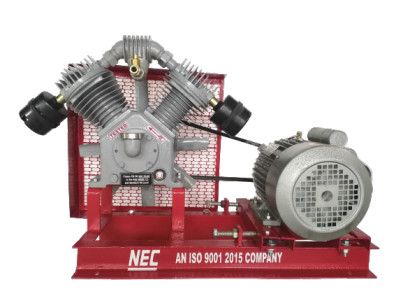

Borewell Compressor Pumps

Domestic Borewell Compressor in coimbatore

Borewell Depth up to 500 Feet

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

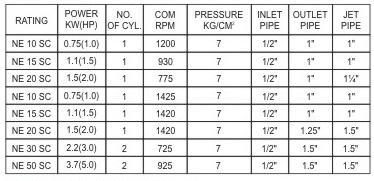

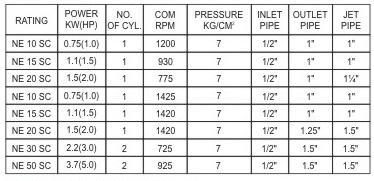

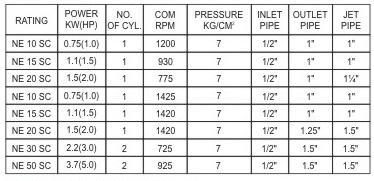

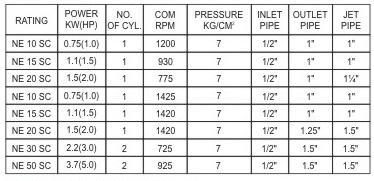

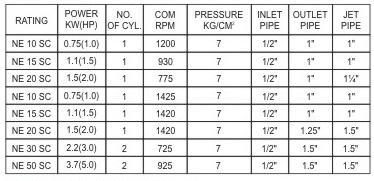

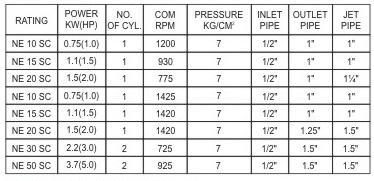

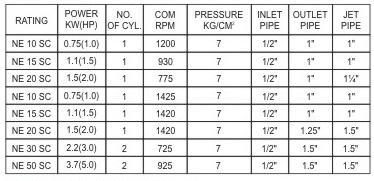

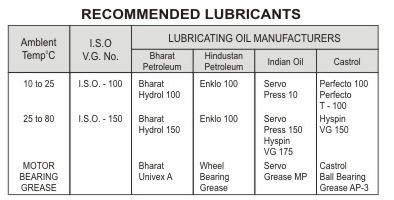

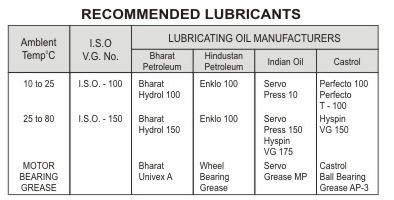

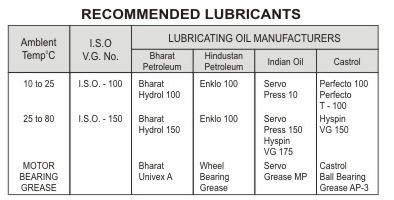

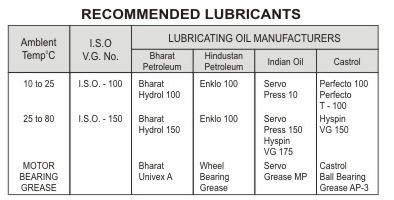

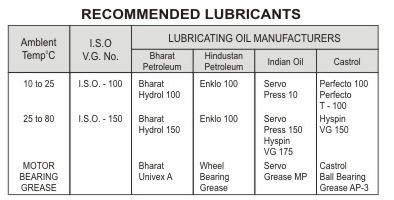

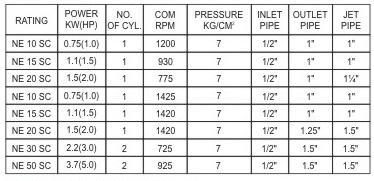

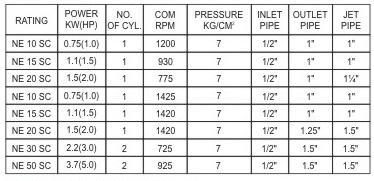

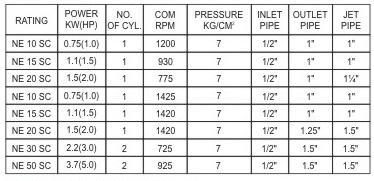

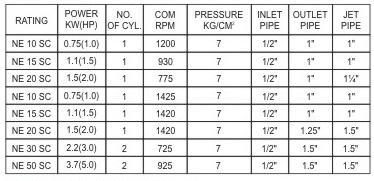

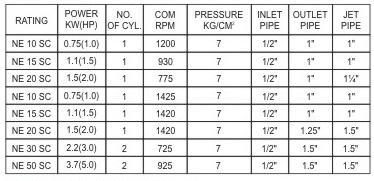

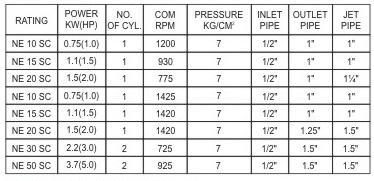

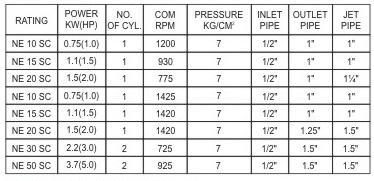

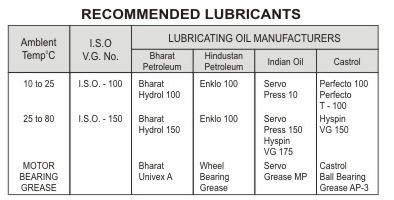

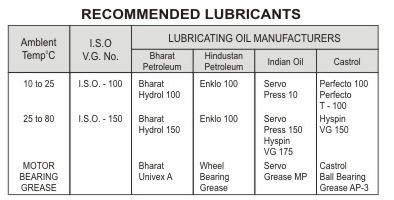

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

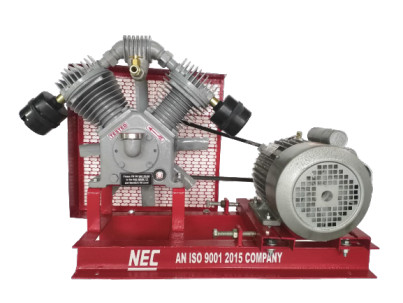

Borewell Mono Compressor Pumps

Borewell Depth up to 500 Feet

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

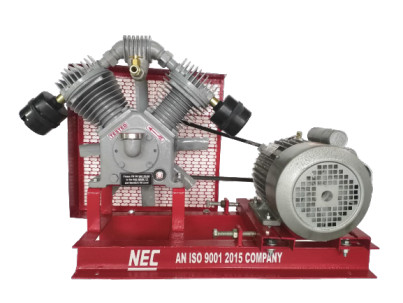

Borewell Mono Compressor Pumps

Mono 90

Borewell Depth up to 300 Feet

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

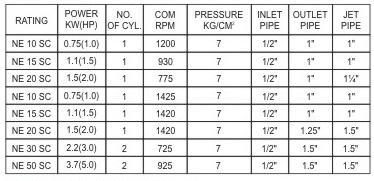

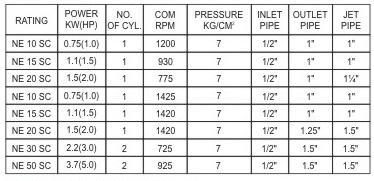

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Borewell Engine Cuppled Compressor Pumps

Borewell Depth up to 1000 Feet

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Double Cylinder Borewell Compressor Pumps

Borewell Depth up to 700 Feet

Domestic HF 200

Single Phase / Three Phase

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

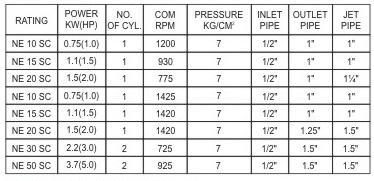

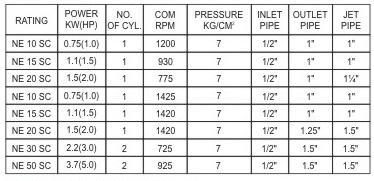

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Technical Data

Double Cylinder Borewell Compressor Pumps

Borewell Depth up to 1000 Feet

Domestic HF 300

Single Phase

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Technical Data

Double Cylinder Borewell Compressor Pumps

Borewell Depth up to 1200 Feet

Domestic / HF 300-D2

Three Phase

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

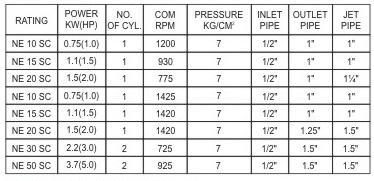

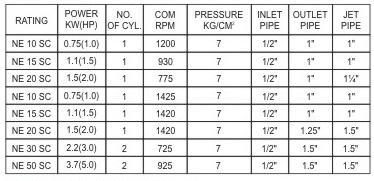

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Technical Data

Double Cylinder Borewell Compressor Pumps

Borewell Depth up to 1300 Feet

Domestic / HP 300

Available 1 Phase / 3 Phase

Product Descriptions

“NEC” Compressor Pumps designed for Domestic and Industrial purpose with High Operating Efficiency and work at the depth of 1200 feet at single Phase , Depth of 2000 Feet at Three Phase , Compressor is coupled with high quality motors to ensure the efficient performance. It works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one operation. The Compressed air is pumped down into the well and gets mixed with water into the delivery pipe as very fine air bubbles by the air – distributor installed at the end of the air pipe line. This air – water mixture having a low density than the surrounding water column rises in the discharge pipe. On continuation of this process, water is pumped through the discharge pipe. These Pumps are robust in construction and tested at high standard excellence.

Performance Chart

Applications

- Domestic

- Agricultural

- Low Yield Borewells

- Hotels

- Apartments

- Industrial Purpose

- Drinking Water Supply

- Multi Borewell Functions

Features

- Detachable compressor cylinder make cleaning easy

- Provision of fool proof indicator to check the oil level clearly whenever required

- Robust construction withstanding overload

- Compact Design

- Available in Single and Double cylinder design

- Special duty motor suitable for compressor

- Specially designed cast iron cylinder with deep finned for better heat dissipation

Material of Constructions

| Product | Material |

| Cylinder | FG260 / 60 / 40 Graded Castiron |

| Piston | Graded Aluminium alloys |

| Rings | Carbon and Graphite |

| Valve Blide | Stainless Steel |

| Valve Plate | MS |

| Crank Assembly | Forged Nickle base alloy steel |

| Housing | Cast Iron |

| Bush | LTB5 |

| Air filter assembly | MS With Air Filter Elements |

| Fabrications | MS Heavy |

| Breather | Aluminium |

| Bearings | Needle / Ball Bearings |

Technical Data

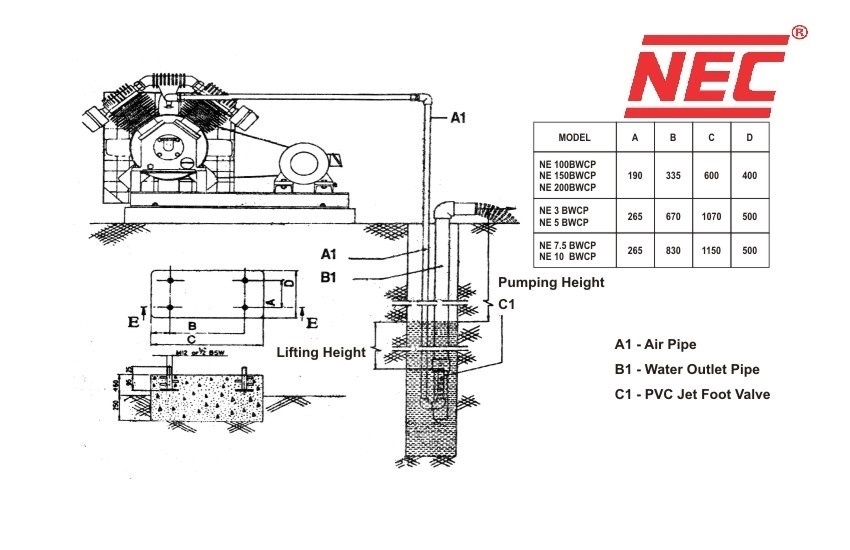

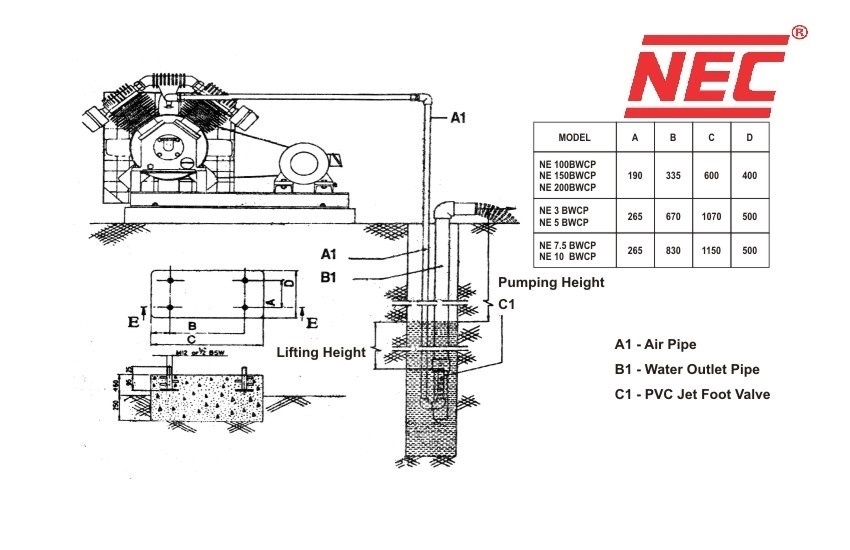

Borewell Compressor Pumps Installations Drawing

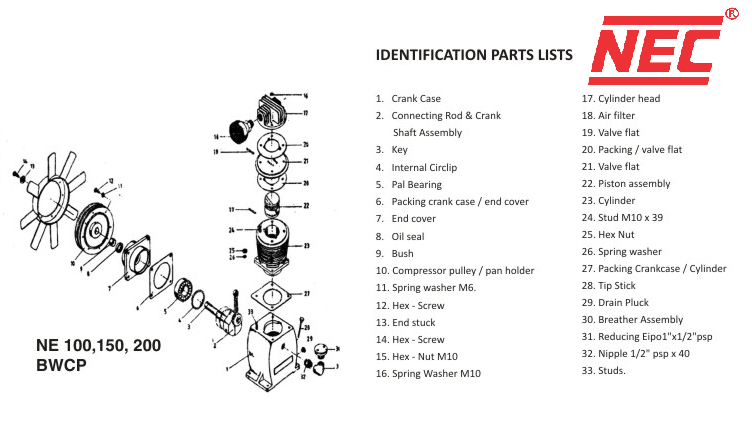

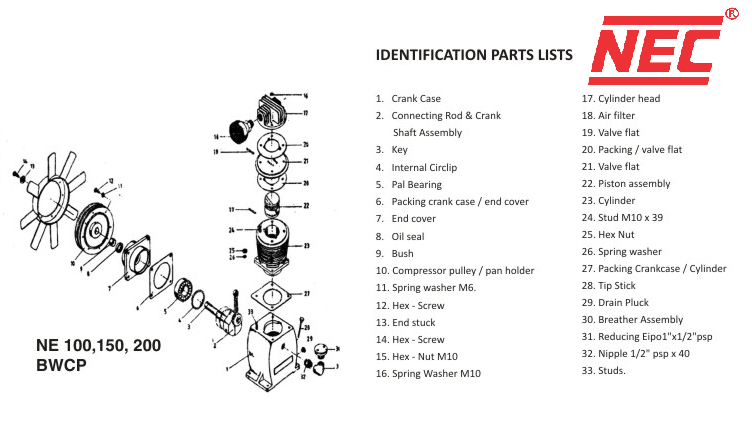

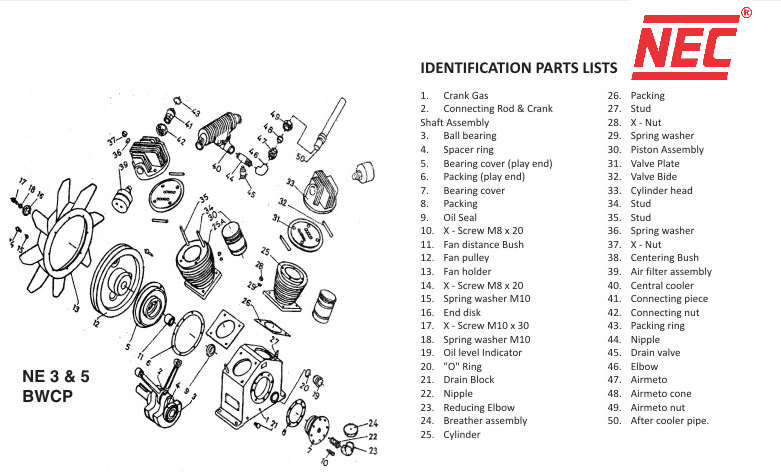

Single Cylinder Borewell Compressor Pumps Parts List

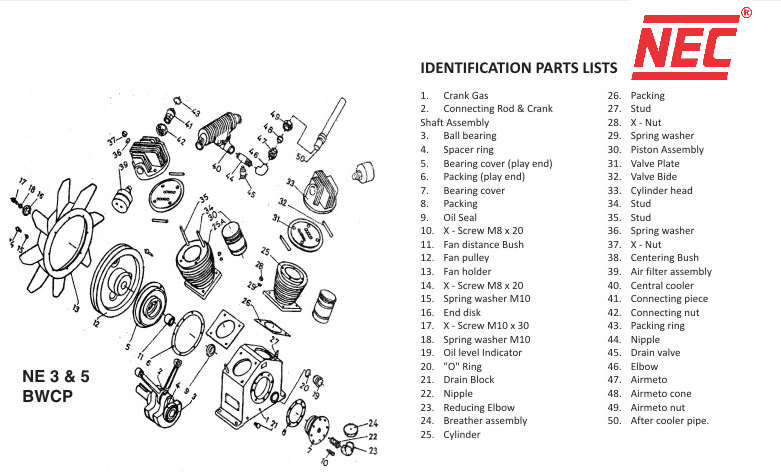

Double Cylinder Borewell Compressor Pumps Parts List

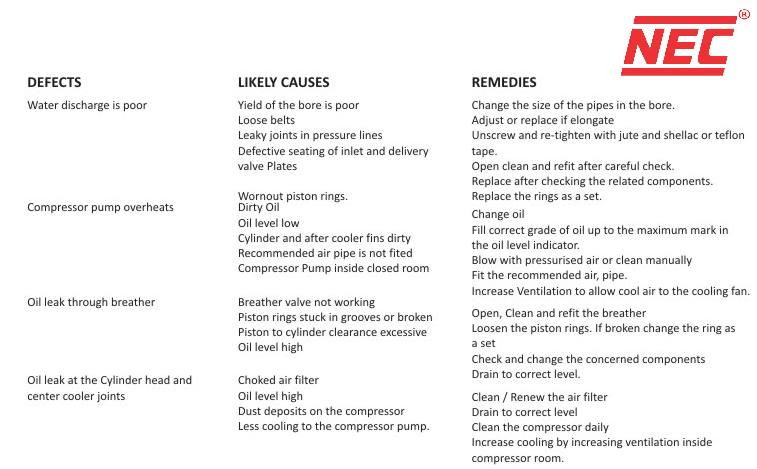

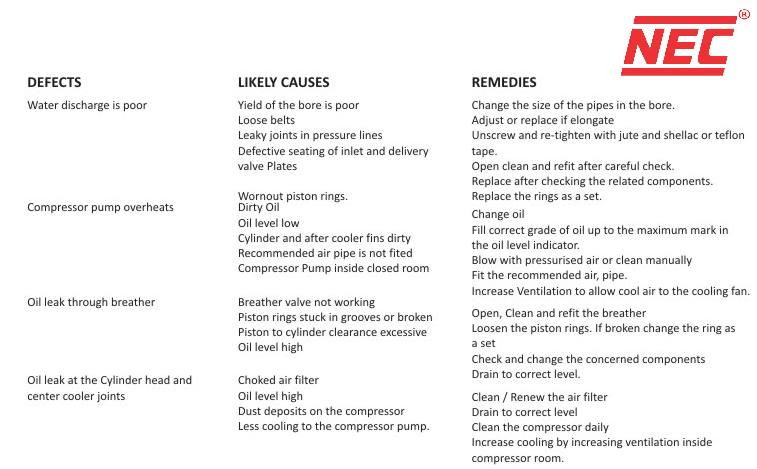

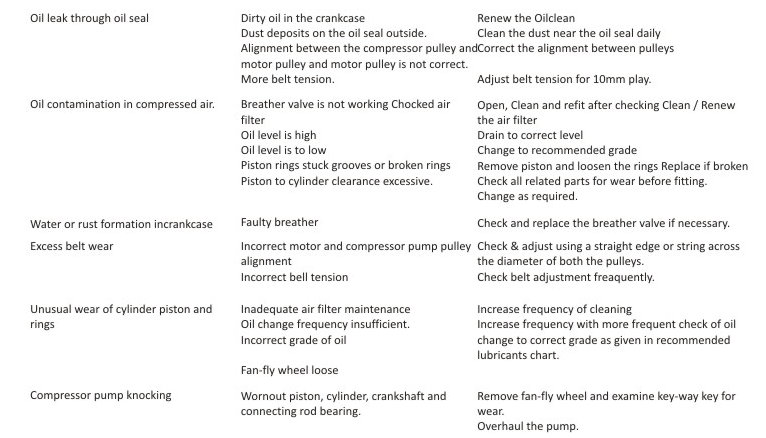

Fault Diagnosis Chart

We, National Equipment Company invented in the year 1988, being as a best manufacturer and supplier is moving ahead in the market with a mission to provide our customers with the qualitative array of Pumps and Air Compressors. We satisfy our clients by providing them with the most prominent array of Air Compressor, Mon block Pump and Refrigerated Air Dryer. Leveraging on our years of experience in the domain we are known for serving most innovative & latest grade products that’s particularly designed to be used in the Industrial pump and HVAC enabled applications. Tamil Nadu We are backed by skilled professionals of industry that assists us in bringing out finest array of facilities as desired by the customer’s. We are interested in buyers from south India Tamil Nadu only. We supplied of lot of Pressure Pump manufacturers Tamil Nadu

NEC The borewell compressors pump works on the principle of difference in density of two-inter-connected water columns and the heavier one over balancing the lighter one. Water outflow through delivery pipe will be pulsated. the discharge of water will greatly depend on the yield of the bore. Air distributor fitted at the end makes this operation possible.

Air Compressor Cylinder

Cylinders of the reciprocating compressor are used in the process industries are separable from the frame. They are attached to the frame by way of an intermediate part known as the distance piece. The cylinder will accommodate the both suction and discharge valve plates.

Normally most of the cylinders used in the process are equipped with replaceable liners. The purpose of the liner is to provide a renewable surface to the wearing portion of the cylinder. This saves the cost of replacing a complete cylinder once the bore has been worn or scored. In the larger, more complex compressors, this feature is standard or readily available as an option. On the smaller frames, particularly the single-stage models, the smaller cylinder size is such that the replaceable liner is not economical and may not be available.

The cylinders are equipped for cooling to reduce the temperature during the compression cycle. This is usually by means of a water jacket. If water jacketing in the cylinder is not feasible than fins are provided in the cylinder for air cooling. The latter method is limited to either small or special purpose machines.

The most common material used in cylinder construction is cast iron for the larger, low-pressure cylinders and steel for the smaller, high-pressure cylinders. In some cases, nodular or ductile iron can be used in lieu of cast iron. For hydrocarbon service, steel is most desirable, although not universally available.

For capacity control, clearance pocket included in the cylinders. In the case of multi-stage compressors, the clearance pocket is used in the first stage cylinder.

Compressor Cylinder Head

All industrial reciprocating compressors are equipped with Crosshead. The crosshead is used to guide the piston in the cylinder bore. The following are the advantage of crosshead

- The compressor can use a narrow piston, due to the use of narrow piston larger valve area for greater efficiency.

- Permits a longer stroke and greater capacity.

- Separates crankcase from the cylinder, allowing control of oil carryover into the cylinder.

- Gives greater stability to piston, eliminating piston “slap” and reducing ring wear

Bearing

The main and connecting rod bearings should be split-sleeve, steel-backed, babbitted insert type. Antifriction bearing shall be used for compressor rating less than 150kW. As per API 618 trapper roller bearings are used as the main bearing for compressor rating less than 150kW.

The cross head pin should have a replaceable bush bearing

Connecting Assembly

For reciprocating compressor of above 150 kW(200 hp), have forged steel connecting rod are used and for compressor less than or equal to 150kW machines ductile iron material is used. Like Crankshafts, the connecting rod should have drilled hole for oil passage. The connection rod is used to connect the crankshaft and the crosshead. The connecting rod converts the rotary motion into reciprocating motion. The connecting rod bolts and nuts shall be securely locked with cotter pins or wire after assembly. For reciprocating compressor of above 150 kW(200 hp), have forged steel connecting rod are used and for compressor less than or equal to 150kW machines ductile iron material is used. Like Crankshafts, the connecting rod should have drilled hole for oil passage.

The connection rod is used to connect the crankshaft and the crosshead. The connecting rod converts the rotary motion into reciprocating motion. The connecting rod bolts and nuts shall be securely locked with cotter pins or wire after assembly.

Piston

The piston is the heart of the reciprocating compressor. The piston translates the energy from the crankcase to the gas in the cylinder. In order to avoid the leakage of compressed gas between the piston and cylinder, the piston is equipped with a set of sliding seals called as piston rings. Usually, the rings are made of a material, that having self-lubricating property to reduce the slide friction force between the cylinder and the piston. This to avoid the wear in the cylinder wall and also increase efficiency by reducing the friction force.

In the case of non-lubricated service, the rings shall have good self-lubricated property. Usually, this type of piston ring is made up of PEEK and other fluorocarbon compounds.

Nowadays the compressor manufacturer preferred non-metallic materials because of less weight when compare with metallic rings.

In the case of horizontal cylinder piston, along with piston rings, an additional ring is used to reduce the avoid the wear between cylinder and piston it is called as wear band or rider ring. The rider ring is one piece configuration, to accommodate the rider ring the piston is segmented construction. As per API 618 one-piece rider rings are a required. Rider band life can be extended by rotating a piston 120° to 180° at each overhaul.

Normally the piston is made up of lesser weight materials such as aluminium and aluminium alloys, this is to reduce the reciprocating compressor shaking forces and Rod load. In the case, piston diameter larger piston diameter hollow pistons are also used to reduce the weight.

Rings

The tangent ring is cut into three segments so that each cut lies on the side of an equilateral triangle. The cuts of this ring maintain sealing contact regardless of variations of the ring’s inside diameter. As wear occurs, the ring segments will close radially to compensate while still maintaining sealing contact at the tangential joints by mean of Garter Spring .

Crank Shaft

Larger compressors, normally above 150 kW(200 hp), have forged steel crankshafts. for compressor less than or equal to 150kW machines ductile iron crankshaft. Crankshafts should have removable balance weights to compensate for rotary unbalance as well as reciprocating unbalance. The crankshaft should be dynamically balanced when above 800 rpm.

When force lubrication is used, the crankshaft oil passages should be drilled. The Figure shows a drilled crankshaft. In the case of machines above 150kW,