Pet Air Compressors in Karur Tamilnadu

PET AIR COMPRESSORS

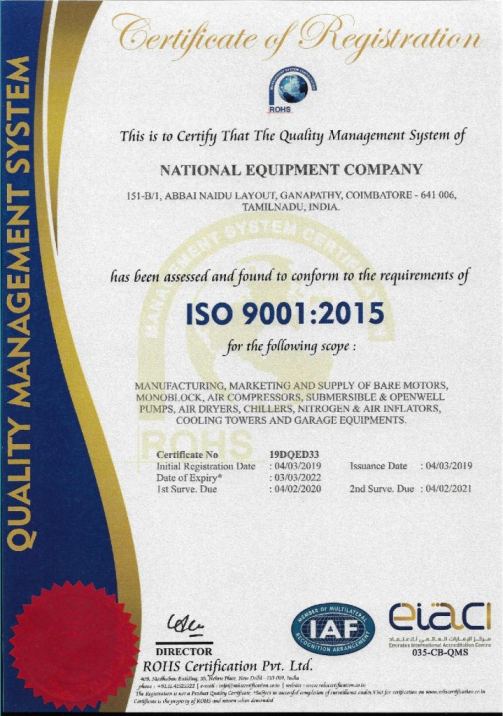

AN ISO 9001:2015 CERTIFIED

THE QUALITY MANAGEMENT SYSTEM

National Equipment Company

Leveraging on our vision to achieve sustainable growth and success, We National Equipment Company have established ourselves as an eminent Agricultural Pumps and Domestic Pumps in the Year 1988 , From the Year of 1994, we have started Reciprocating Air Compressors, Garage Equipments, Manufacturer and trader of India.

We are well known for our our never compromising quality control policy for our product range as well as services with hold on ISO 9001:2015 certification. Due to the unparalleled quality of our products, we have acquired the membership of CODISSIA, SIMA, TAPMA, SITARC, COPMA, COCIA .Owing to transparent business policy and impeccable quality products, our organization has gained immense popularity across the country, to render services, hence we supply our products to all the States in India through Distributors, Dealers and now in Online Customers .

We Proud to say we Honored with an Awards

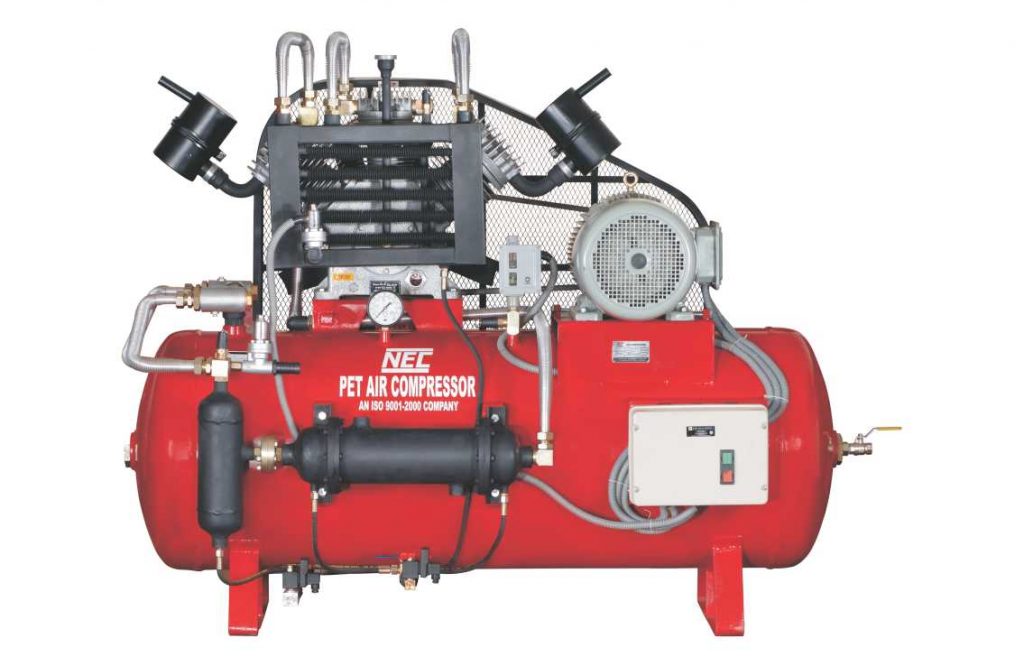

PET AIR COMPRESSOR

1515Jumbo Model

1010 Jumbo Model

Product Description

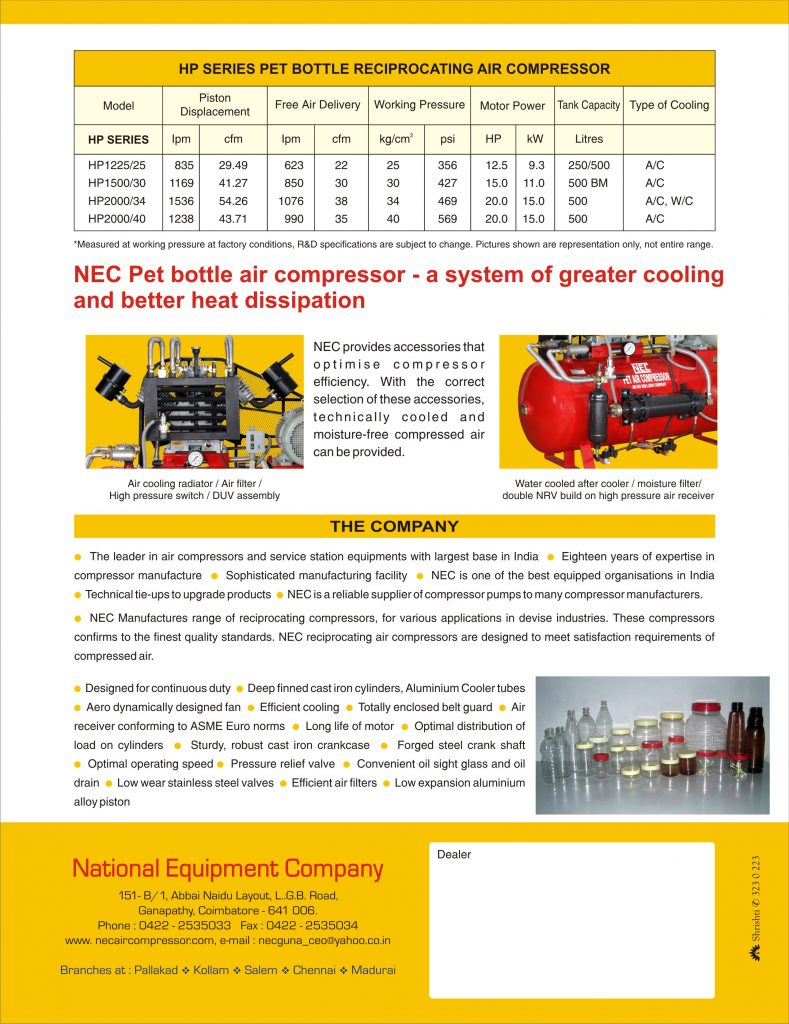

“NEC” High volume compressor is meticulously designed with cutting-edge technology proven around the world.It is simple to operate and easy to maintain.And with an extensive service network and easy availability of spares,this compressor is undoubtedly the wisest choice for unparalleled performance in the long run.

Applications

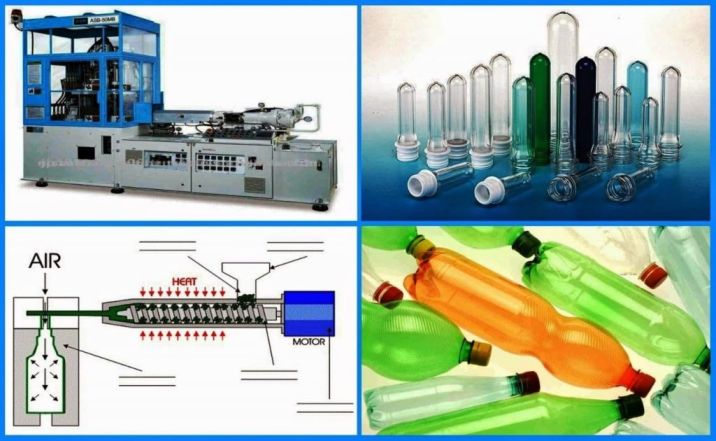

The high pressure range of compressors is suitable for usage in the range of 30-40 bar for applications like engine starting, circuit breakers and marine applications.

- Plastic & packaging industry

- Circuit breaking

- Thermal power projects

- Genset starting

- PET blowing

Features

- Cast iron cylinders and cylinder heads with deep grooved cooling fins ensure best possible heat transfer and keeps the compression system relatively cool

- Aluminium pistons with piston rings to ensure lower wear and tear and lower oil carry over into the compression chamber.

- Strong and robust crank case is made of high grade cast iron. Splash lubrication system ensures proper circulation of oil to all parts of the rotating system.

- Precise and sophisticated suction valves with unloader and delivery valves reliability is assured

Material of Constructions

| Topblock | Robust 3 stage high pressure block for the best efficiency |

| Suction Filter | Heavy duty air filter with enhanced life |

| Electric Motor | Heavy duty, TEFC, CE Certified designed for 50°C ambient with IP55 protection & class F insulation |

| Delivery Un-loader | Solenoid controlled automatic bleeding of compressed air to ensure smooth starting |

| Starter | Dual operattion Mode (Load/un-load and on/off) at a single touch |

| Inter & Aftercoolers | Robust air cooled inter stage and after stage copper coolers |

| V-Belts | Double poly V Belts with low transmission loss |

| Safety valves | 4 safety valves for enhanced safety |

| Suction Unloaders | Runs the compressor in un-load mode where is no demand |

| Belt Guard | Close mesh belt guard to prevent accidental injury to the operator as per international safety norms |

| Air Receiver | 500 Lts high pressure receiver designed as per ASME standards |

| Bearings | High quality ball bearings and roller bearings ensures optimum load transfer and transmission without causingg any un-even wear |

| 3 piece forged Crank shaft and forged connecting Rods | with a high mechanical life offers even throw and makes the compression system run smooth without any unwanted vibration |

Technical Specification

| Model | Motor power | Motor | Piston Displacement | Free Air Delivery | Comp.Speed | Max. Pressure | Air Receiver | Net weight | Dimension | ||||

| HP | kw | RPM | cfm | lpm | cfm | lpm | rpm | bar(g) | psi | Ltrs. | kg | LxBxH (mm) | |

| TS15TR/7/500 | 15 | 11.0 | 1440 | 67.7 | 1917 | 60.9 | 1725 | 925 | 7 | 100 | 500 | 514 | 1915x875x1505 |

| TS200TR/7/500 | 20 | 15.0 | 1440 | 87.5 | 2477 | 78.7 | 2229 | 1050 | 7 | 100 | 500 | 530 | 1915x875x1505 |

| Jumbo1010 | 20 | 15.0 | 1440 | 95.5 | 2704 | 85.9 | 2433 | 1050 | 7 | 100 | 500 | 615 | 1915x1170x1550 |

| Jumbo1515 | 30 | 22.5 | 1440 | 102.0 | 2888 | 91.8 | 2599 | 820 | 7 | 100 | 500 | 655 | 1915x1170x1550 |

| Jumbo2020 | 40 | 30.0 | 1440 | 118.0 | 3341 | 106.2 | 3006 | 820 | 7 | 100 | 500 | 680 | 1915x1170x1550 |

| TS15TR/10/500 | 15 | 11.0 | 1440 | 65.7 | 1860 | 49.1 | 1390 | 925 | 10 | 145 | 500 | 514 | 1915x875x1505 |

| TS200TR/10/500 | 20 | 15.0 | 1440 | 75.0 | 2123 | 67.5 | 1910 | 1050 | 10 | 145 | 500 | 530 | 1915x875x1505 |

| Jumbo1010 | 20 | 15.0 | 1440 | 86.0 | 2435 | 77.4 | 2191 | 1050 | 10 | 145 | 500 | 615 | 1915x1170x1550 |

| Jumbo1515 | 30 | 22.5 | 1440 | 94.0 | 2661 | 84.6 | 2394 | 820 | 10 | 145 | 500 | 655 | 1915x1170x1550 |

| Jumbo2020 | 40 | 30.0 | 1440 | 102.0 | 2888 | 91.8 | 2599 | 820 | 10 | 145 | 500 | 680 | 1915x1170x1550 |

| TC1500TR/12/500 | 15.0 | 11.0 | 1440 | 54.3 | 1538 | 44.1 | 1249 | 1150 | 12 | 175 | 500 | 470 | 1915x875x1420 |

| TC2000TR/12/500 | 20.0 | 15.0 | 1440 | 66.6 | 1885 | 59.9 | 1696 | 1050 | 12 | 175 | 500 | 500 | 1915x875x1420 |

AIR DRYER

High Pressure Refrigerated Air Dryer

Product Description

- Copper “Tube in Tube” non corrosive heat Exchange, designed to have lower pressure drop and higher efficiency contains in built centrifugal moisture separator having dead zone to avoid carry over of condensate.

- PUF insulation for heat exchange assembly.

- Electronic timer operated Auto Drain Valve.

- Universally available refrigeration components like Compressor , Fan motor, Filter dryer, Expansion Valve etc.

- Non cyclic refrigeration systems , with the help of hot gas bye pass Solenoid Valve , for varying load condition and seasonal adjustments.

- NEC Reduced energy consumption: Patented heat exchanger, precooler/reheater, low pressure loss and R134a refrigerant lower your energy costs .

Applications

- Cement

- Laundry

- Lumber

- Food Processing

- Printing

- Pulp and paper

Features

- Complete range with ozone friendly refrigerant

- Compact in size

- Wide range

- Lower power consumption

- Reliable components

- Consistent dew point

Material of Constructions

Technical Specification

| Airflow | Ref. Power | Electrical Connection* | In/Outlet | Dimensions | Weight | |||||

| CFM | m³/h | kW* | 220V / 1Ø/50Hz | 415V / 3Ø/50Hz | BSP | A | B | C | kg. | |

| ARD20 | 20 | 34 | 0.21 | ok | ½” | 360 | 475 | 550 | 45 | |

| ARD40 | 40 | 68 | 0.36 | ok | ½” | 360 | 475 | 550 | 47 | |

| ARD60 | 60 | 100 | 0.36 | ok | ½” | 360 | 475 | 550 | 47 | |

| ARD80 | 80 | 136 | 0.48 | ok | 1″ | 500 | 600 | 730 | 78 | |

| ARD100 | 100 | 170 | 0.6 | ok | 1″ | 500 | 600 | 730 | 90 | |

| ARD150 | 150 | 255 | 0.68 | ok | 1″ | 500 | 600 | 730 | 90 | |

| ARD200 | 200 | 340 | 1 | ok | 1½” | 700 | 700 | 830 | 120 | |

| ARD250 | 250 | 425 | 1.4 | ok | 1½” | 700 | 700 | 830 | 135 | |

| ARD300 | 300 | 510 | 1.4 | ok | 1½” | 700 | 700 | 830 | 135 | |

| ARD400 | 400 | 680 | 1.8 | ok | 2″ | 900 | 900 | 1230 | 170 | |

| ARD500 | 500 | 850 | 2.2 | ok | 2″ NB flg | 900 | 900 | 1230 | 180 | |

| ARD750 | 750 | 1275 | 3.3 | ok | 2″ NB flg | 750 | 1000 | 1400 | 250 | |

| ARD1000 | 1000 | 1700 | 4.2 | ok | 2″ NB flg | 900 | 1200 | 1475 | 350 |

WATER CHILLER

COOLING TOWER

STAGE MONOBLOC

Catalogues